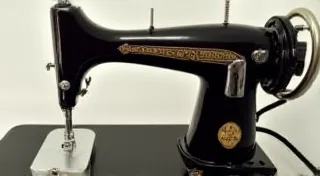

Lubrication Guide for Vintage Singer Sewing Machines

Maintaining your vintage Singer sewing machine involves more than just cleaning; proper lubrication is vital for its smooth operation, longevity, and overall health. Neglecting lubrication can lead to increased friction, premature wear, and potentially costly repairs. This guide will walk you through the process of lubricating your antique Singer sewing machine, covering suitable lubricants and application techniques.

Why Lubrication Matters

Vintage Singer sewing machines are intricate mechanical marvels. Moving parts—gears, levers, bearings—create friction, generating heat and causing wear. Lubrication minimizes this friction, reducing heat and extending the life of your machine's components. Old grease can harden and lose its effectiveness, while rust can form without adequate protection. Regular lubrication helps prevent these issues. The complexity of these machines means understanding subtle mechanical problems can be tricky. You might find yourself, like many vintage Singer enthusiasts, needing to diagnose the ghost in the gears – those subtle maladies that impact performance. Recognizing the need for thorough lubrication is often the first step in resolving such issues.

Choosing the Right Lubricant

Selecting the appropriate lubricant is crucial. Here's a breakdown of options, with considerations for each:

- Sewing Machine Oil: This is generally the *best* option. Specifically look for a lightweight, multi-grade sewing machine oil. It's designed to flow well at different temperatures and won't gum up over time.

- 3-in-1 Oil: While readily available, 3-in-1 oil tends to evaporate more quickly than dedicated sewing machine oil, requiring more frequent applications. It's acceptable for light use but not ideal for a comprehensive lubrication.

- Mineral Oil: Can be used in a pinch, but ensure it’s a lightweight variety. Avoid heavier mineral oils.

- Avoid: WD-40, silicone sprays, and other penetrating oils. These aren’t suitable lubricants and can damage certain parts over time. The motor, in particular, requires careful attention. If you’re dealing with issues specific to a Singer Featherweight motor, it’s worth delving into understanding its repair and maintenance to ensure optimal performance – and the right lubrication strategy.

Lubrication Points – A Step-by-Step Guide

Before you begin, ensure your machine is clean. Dust and debris can contaminate the lubricant. Use a brush and a lint-free cloth to remove any buildup. Pay close attention to the handwheel and its associated components; proper function relies on smooth rotation. Should you need to replace the handwheel, you might find it beneficial to consult a guide like Singer 12: Replacing the Handwheel - A Practical Guide.

- Bobbin Case and Shuttle Race: Apply a *tiny* drop of oil to the bobbin case and inside the shuttle race. Too much oil here will attract dust and create a sticky mess.

- Needle Bar and Presser Bar: Oil the needle bar and presser bar pivot points.

- Motor (if applicable): The motor requires lubrication. Consult your specific Singer model's manual for instructions. Often, there are specific oiling points on the motor itself. This can be a complex process, best handled with a focused resource.

- Drive Train: Carefully apply oil to the gears and levers in the drive train. Again, use a small amount - just enough to coat the surfaces.

- Handwheel and Crankshaft: Oil the bearings where the handwheel and crankshaft rotate.

- Timing Lever and Cam: A small drop of oil at the pivot points of the timing lever and on the cam itself is crucial for smooth operation.

Application Techniques

- Use a small oiler: This gives you precise control, preventing over-oiling.

- Apply sparingly: Less is more! Over-oiling attracts dust and can cause problems.

- Wipe away excess oil: Use a lint-free cloth to wipe away any excess lubricant.

- Consult your manual: Your Singer model's manual is the *best* resource for specific lubrication instructions and diagrams. If you don’t have the original manual, many are available online. Understanding the nuances of each model's lubrication points is key to longevity.

Frequency of Lubrication

The frequency of lubrication depends on how often you use your machine and the environment it’s stored in. As a general rule:

- Heavy Use: Every 10-15 hours of sewing.

- Moderate Use: Every month or so.

- Infrequent Use: Every 3-6 months.

Beyond regular lubrication, the aesthetic condition of your machine also plays a role in its overall health. A well-maintained machine, both mechanically and cosmetically, is a joy to own and operate. If you're looking to enhance the appearance of your machine, consider tackling a project like Restoring a Singer 201: Polishing the Machine Body to bring out its original luster.

Troubleshooting Lubrication Issues

Even with meticulous lubrication practices, issues can arise. Excessive noise, sluggish operation, or unexpected jams can all be signs of lubrication problems. Here's a breakdown of common issues and potential solutions:

- Excessive Noise: This could be caused by insufficient lubrication, old or hardened grease, or even debris interfering with moving parts. Thorough cleaning and re-lubrication are usually the first steps.

Long-Term Care and Preservation

Lubrication isn’t the sole aspect of vintage Singer sewing machine maintenance. Proper storage is also critical. Store your machine in a clean, dry environment away from extreme temperatures and humidity. Regularly dust the machine and occasionally wipe down the surfaces with a soft cloth. Periodic inspection and preventative maintenance, including lubrication, will extend the life of your treasured machine for generations to come.

Conclusion

Regular and proper lubrication is a simple yet essential aspect of vintage Singer sewing machine maintenance. By following this guide, you can help ensure your machine continues to operate smoothly and reliably for years to come. Always prioritize cleanliness and use appropriate lubricants for optimal performance and longevity. Remember that a little bit of preventative care goes a long way in preserving the legacy of these remarkable machines.